MykoFoam: The carbon negative mushroom insulation

Product description

MykoFoam is a type of rigid insulation developed by Mykor, made from mycelium the root structure of fungi. It is formed by naturally binding mycelium to waste materials generated by paper and pulp production. This unique insulation is not only renewable and bio-based, but also boasts a manufacturing process that has a negative impact on carbon emissions. In addition to its environmental benefits, MykoFoam has excellent thermal and acoustic properties, making it a highly effective insulation material.

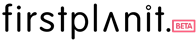

Firstplanit Evaluation

When Firstplanit assessed MykoFoam against 18 key impact indicators, the product achieved “best practice” classification for two categories: rapid degradability (within one year) and rapid renewability (also within one year). In addition, MykoFoam emerged as a top performer in three other areas: low embodied carbon (213 kgCO2eq/m3), versatility (thanks to its modular design, easy installation and removal, and ability to maintain its properties when cut down), and acoustic regulation (with an NRC of 0.75).

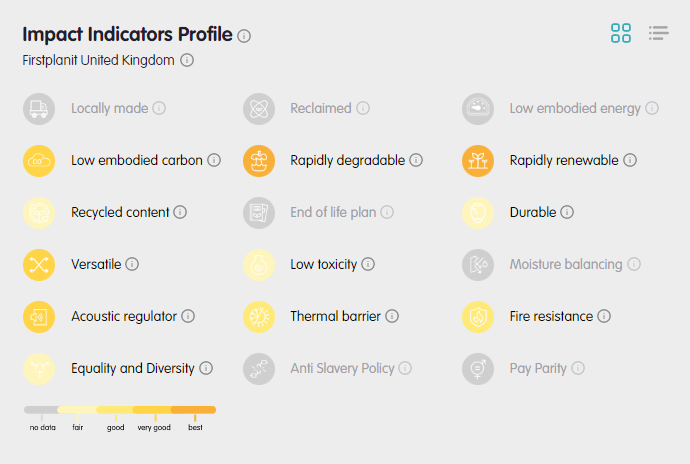

After evaluating MykoFoam’s performance across all 18 sustainability metrics, a product score was calculated for Environment, Social, Health and Monetary. This score was then compared against a non-sustainable product that is currently prevalent in the market. To quantify the benefits of using MykoFoam over the conventional alternative, a benefit score was derived by comparing their respective product scores.

MykoFoam surpassed the industry standard alternative across all metrics, with its strongest performance being in the environmental category.

Application and manufacturing process

The product can be used in construction for interior spaces, both exposed and not exposed, and exterior rendered.

The fabrication technique used for MykoFoam involves inoculating and propagating mycelium on cellulosic waste using a process rooted in mycology. This 4-week manufacturing process requires minimal water and low temperatures.

Compared to Expanded Polystyrene Insulation (EPS), Mykor’s manufacturing process consumes 90% less water, 40% less energy, and produces 60% less CO2 emissions.

The raw materials used to make MykoFoam are sourced from The Navigator Company, a paper manufacturer that generates 1.6 million tonnes of waste annually.

The MykoFoam factory is located in Portugal, near the waste site, to reduce the transportation distance of the cellulosic waste feedstock.

Company Purpose and founders

The company’s aim is to develop top-quality building materials from waste using carbon-negative manufacturing methods.

The ultimate goal is to become waste-negative, meaning that the company will consume more waste than it produces while also achieving complete circularity in production.

Valentina is an award-winning material designer, with a background in the design industry. Olivia is trained in architecture and is also an internationally renowned project manager.

Additional information

Mykor has a Take-Back policy, for unused products from over orderings. Additionally, the company accepts old used panels for recycling back to create new panels.

Register to Firstplanit

Whether you are are a manufacturer of a sustainable building material, or a project developer sign up and explore the benefits that firstplanit offers you.